Contact Us

Phone/WhtasApp:

+86-13661020713

+86-13261569774

E-mail:

yilia@cngreatpower.com

star@cngreatpower.com

Office:

Tianqi International Building, Binhai, Tianjin, China

Shaped flange

★ Production standard: Chinese standard, American standard, European standard, German standard, Russian standard, Japanese standard, British standard, South African standard;

★ Material: carbon steel, stainless steel, alloy steel;

★ Size:1/2”-120”; DN15-DN3000;

★ Pressure rating:150#; 300#; 600#; 900#; 2000#; 3000#; 6000#; 9000#;

★ Coating: anti-corrosion coating; galvanized;

★ Applications:Construction, chemical industry, electric power, water treatment, petroleum, aerospace, fire protection, industry, shipbuilding, pharmaceuticals, etc.;

★ Remarks:Customized products can be produced according to customer requirements;

- Commodity name: Shaped flange

- Description

-

Shaped flange

1. Production standard:

★Chinese standard:

⊙ National Standards: GB/T9119-2010, GB/T2555-81; GB/T9115.1-2000, GB/T9115.2-2000, GB/T9115.3-2000, GB/T9115.4-2000

⊙ Ministry of Chemical Industry standard HG/T20592-2009, HG20593-2009, HG20615-2009;

⊙ Standards of the Ministry of Machinery: JB/T81-94, JB/T74-94, JB/T75-94; JB/T86.2-94

⊙ Marine standard CB/T47-1999

⊙ Energy industry standard recommendation: NBT47023-2012

★American Standard: ASME B16.5, ANSI

★European standard: EN 1092-1:2007

★German standard: DIN2527, 2573, 2627-2638, 2673, 2552, 2653, 2655, 2656, 2641, 2642, 2565-2569

★Russian standard: GOST12820-80, GOST 12836-80, GOST 12821-80

★Japanese standard: JIS B2220

★British Standard: BS10 TABLE D/E

★South African Standard: SABS 11232. Material:

★Carbon Steel: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

★Stainless Steel: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

★Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ;3. Size:1/2”-120”; DN15-DN3000

4. Pressure level:150#;300#;600#;900#;2000#;3000#;6000#;9000#

5. Coating:Anti-corrosion coating; galvanized.

6. Detection:Chemical composition analysis; Mechanical properties; Metallographic test,; Acid resistance test,; Heat treatment; Ultrasonic test; Penetration test; Magnetic particle test; X-ray detection; Hydrostatic test; Burst test; According to customer needs

7. Application:Construction, chemical industry, electric power, water treatment, petroleum, aerospace, fire protection, industry, shipbuilding, pharmaceuticals, etc.

8. Remarks:Customized products can be produced according to customer requirements

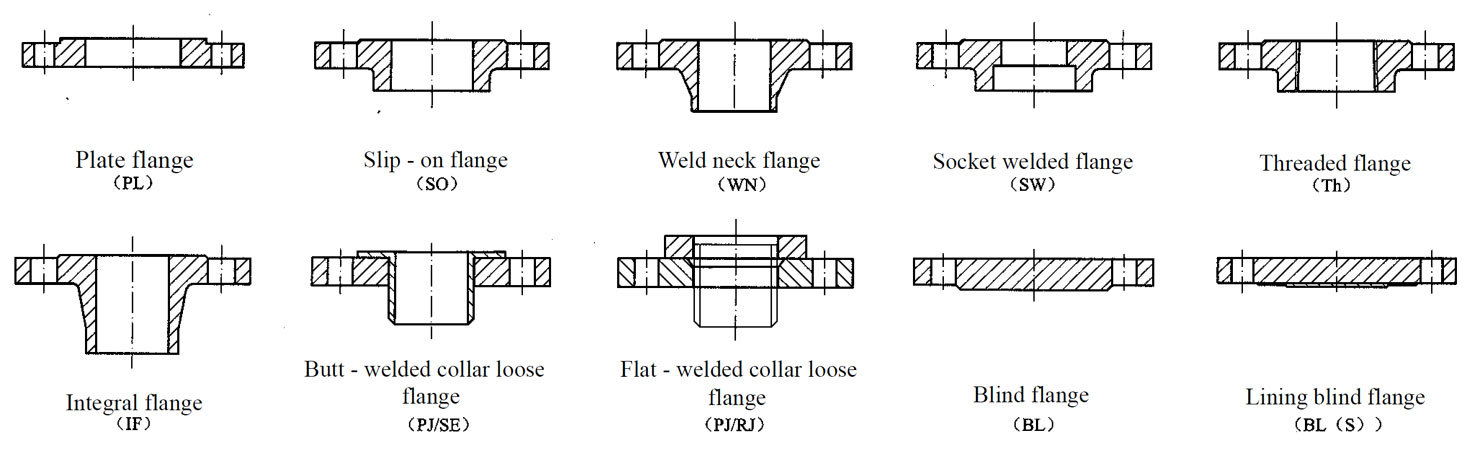

Schematic diagram of flange structure

Product Display

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products